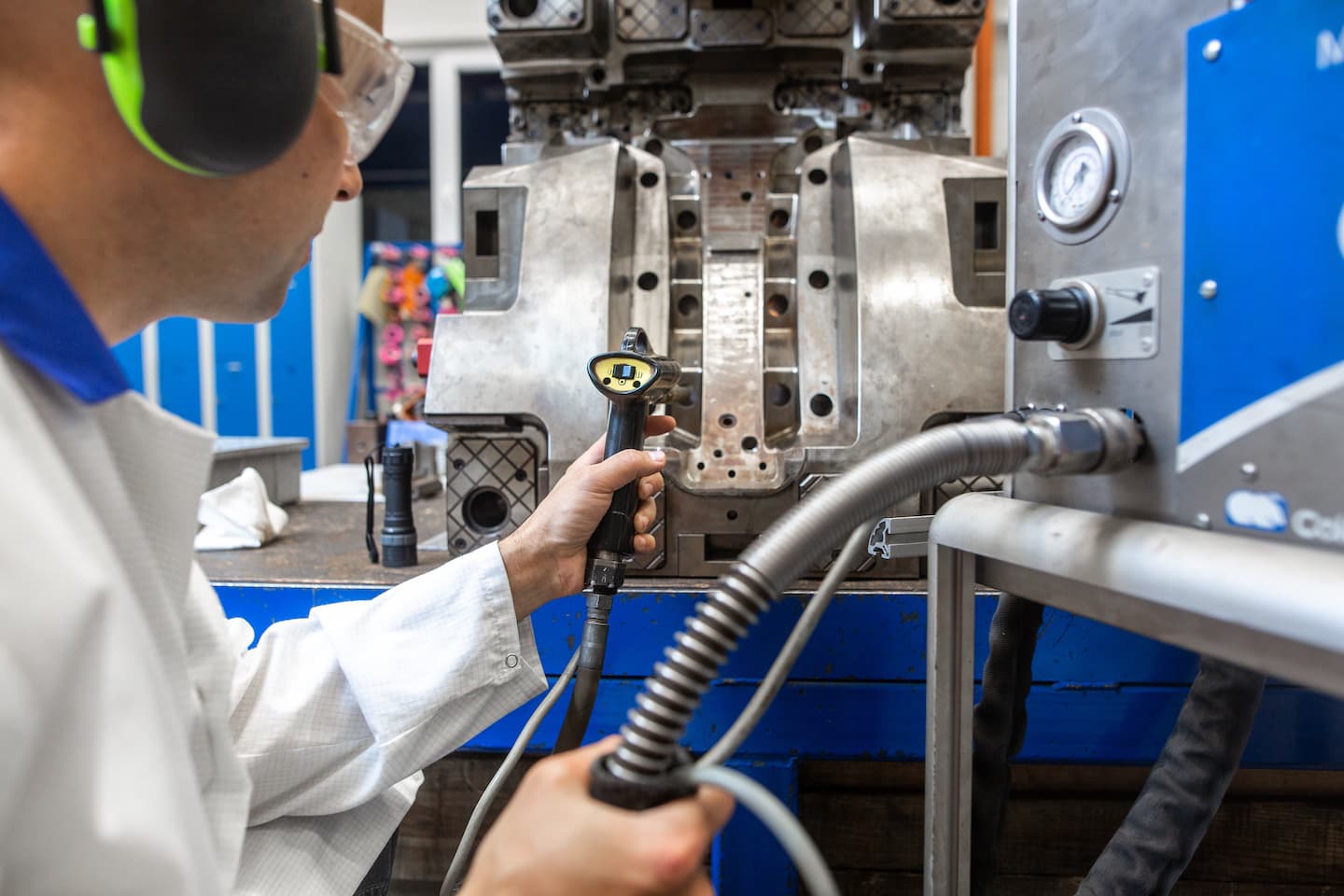

Mechanical engineering production

Our main goal is to provide comprehensive servicesunder one roof of the highest quality, from mold and part design to their manufacture. Our qualified team of experts flexibly responds to individual customer needs with an emphasis on precision and specified technical requirements.

Ing. Sebastian Gerbel, MBA

Executive

Highly qualified workers

The production process is carried out by our highly qualified workers with many years of experience. We use several machines in production, such as wire cutting machines, CNC milling machines, depth gauges , surface grinders and column drills. Thanks to these technologies, we are able to produce products exactly according to customer requirements, whether they are plastic or metal parts.

Tailored design of parts and molds

We are also able to develop CAD designs for custom parts and molds using modern progressive CAD/CAM systems. CAD/CAM solutions are primarily designed for design in the field of injection mold production. We currently work with the Pro/ Engineer Creo3.0 system, which simplifies the subsequent mold production process.

Custom manufacturing

Within the mechanical engineering department, we provide production of precision parts and cooperation work. Our portfolio of services includes CNC milling of custom and small-batch production, mold production (for plastics, non-ferrous metals or alloys), production of complex product fixtures, EDM and production of copper electrodes for EDM directly in the EROWA holder.

Our technologies

Drilling and milling

Description

Designed for precise, high-speed machining of complex surfaces, drilling, boring, reaming and thread cutting. Automatic tool change from the magazine allows work in an automatic cycle, which makes the production process more efficient. The cross table and headstock feeds can be used simultaneously. The machine is equipped with air and coolant supply through the center of the spindle, which significantly increases work productivity.

| Basic technical parameters | |

|---|---|

| Table clamping surface: | 1000 x 640 mm |

| Longitudinal table movement - X-axis: | 750 mm |

| Transverse movement of the table - Y-axis: | 500 mm |

| Vertical table movement - Z-axis: | 500 mm |

| MAximum table load | 650 kg |

| Main spindle speed: | 0-12.000 ot./min |

| Acceleration electro-spindle speed: | 0-60.000 ot./min |

| Control system: | Heidenhain iTNC530 |

Description

Designed for precise, high-speed machining of complex surfaces, drilling, boring, reaming and thread cutting. Automatic tool change from the magazine allows work in an automatic cycle. The cross table and headstock feeds can be used simultaneously. The machine is equipped with air and coolant supply through the center of the spindle, which significantly increases work productivity.

| Basic technical parameters | |

|---|---|

| Table clamping surface: | 1300 x 640 mm |

| Longitudinal table movement - X-axis: | 1016 mm |

| Transverse movement of the table - Y-axis: | 600 mm |

| Vertical table movement - Z-axis: | 600 mm |

| MAximum table load | 750 kg |

| Main spindle speed: | 0-10.000 ot./min |

| Control system: | Heidenhain iTNC530 |

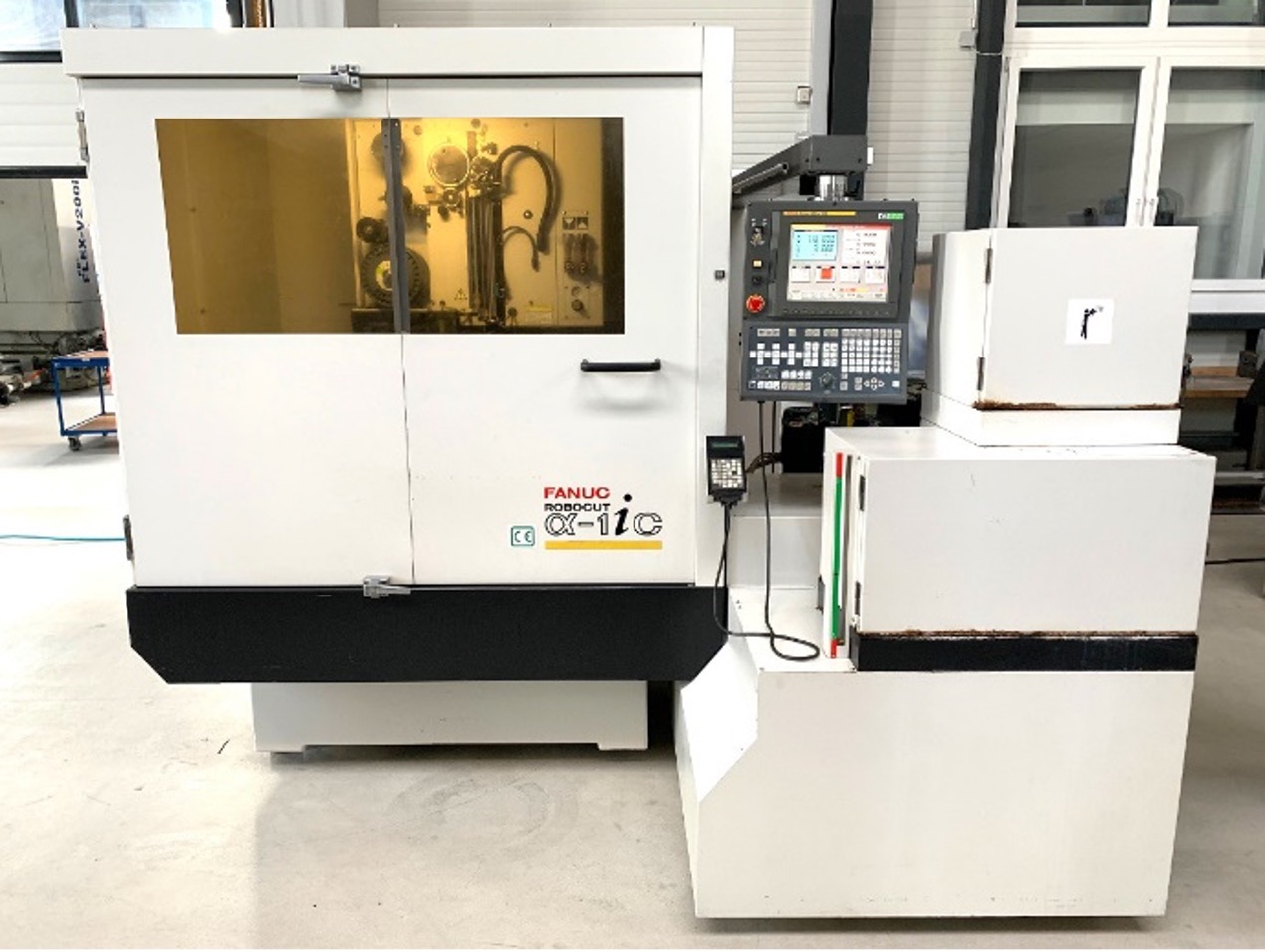

Electrical discharge machining

Description

This machine also allows planetary eroding and C-axis rotation. The machine is equipped with a special option for burning holes and an electrode magazine. We use it mainly for deep-grooving complex shaped parts of molds and components.

| Basic technical parameters | |

|---|---|

| Table dimensions: | 500 x 400 mm |

| X, Y, Z movements: | 350 x 250 x 300 mm |

| Max. workpiece dimensions (w x d x h): | 780 x 530 x 300 mm |

| Min/max distance between table and quill: | 150/450 mm |

| Max. electrode weight: | 50 kg |

| Max. workpiece weight: | 500 kg |

| Clamping system: | EROWA |

Description

High-speed and very precise electric discharge cutting machine is used for cutting precise dimensions of parts for injection molds and cutting tools or other very precise parts.

| Basic technical parameters | |

|---|---|

| Table dimensions: | 770 x 590 mm |

| X, Y, Z movements: | 550 x 370 x 300 mm |

| Max. workpiece dimensions (w x d x h): | 800 x 590 x 300 mm |

| Max. workpiece weight: | 800 kg |

Grinding

Description

The grinder is designed for grinding precise flat parts for injection molds and cutting tools or other precision components.

| Basic technical parameters | |

|---|---|

| Table dimensions: | 405 x 910 mm |

| X, Y movements: | 900 x 400 |

| Max. workpiece dimensions (w x d x h): | 800 x 590 x 300 mm |

| Min/max distance between table and spindle center: | 570 mm |

| Max. workpiece weight: | 500 kg |